We can laser mark and engrave almost any parts you need.

We can laser mark and engrave almost any parts you need.

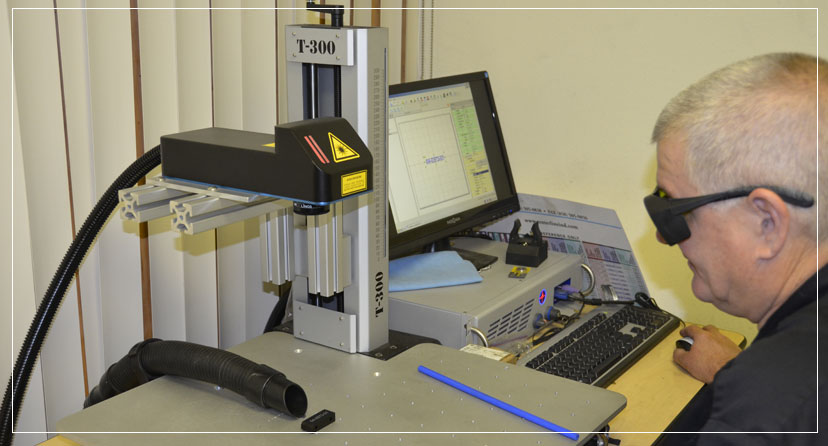

Our high precision laser marking center can do single piece or high volume runs with ease. With traditional or older marking methods there are costs for tool bits, labels, chemicals and other consumable materials that may not create a non-wear surface.

Metals are considered very robust and durable materials and are available in many different types. Laser marking has proved successful for etching metals owing to its durability and the fact that it does not damage the material. Fiber lasers are mainly used for laser marking metals; they are suited for the marking of many different types of metal.

| Aluminum | Brass | Carbide metal |

| Chrome | Coated metals | Eloxal |

| Cobalt | Copper | Silver |

| Gold | Platinum | Titanium |

| Steel | Tin | Zinc |

Marking metals with the laser is an extremely accurate and clean way of working on metal. Markings such as serial numbers, codes and logos can be applied on products and components in maximum resolution. Metal etching and engraving with the laser is contact-less; the metal surface is not damaged.

Typical areas of application for laser marking of metals include product labeling and coding in the electronics industry (mobile phones, iPad – mostly eloxal marking), tool construction, and medical technology. Annealing marking (see below) is an especially suitable process that allows for burr-free marking that is gentle on the material.

Alpha Numeric Serial Numbers

Whether you need a deep engraving of your parts, or contrast only marking the laser engraving process is the right choice. With contrast only marking, you'll get a non-disturbed finish which is ideal for the medical industry and will last for the life of the product. Whereas with deep engraving we can penetrate the surface anywhere from .005" up to .010" deep.

VIEW PHOTO GALLERY