Our Advanced Microelectronics group now offers advanced microelectronics assembly and packaging services, process development, and low to medium-volume production for high-reliability applications. Utilizing our new state-of-the-art equipment and our 45+ years of process expertise, we enable customers to transition from prototype to low-volume production seamlessly.

Our Advanced Microelectronics group now offers advanced microelectronics assembly and packaging services, process development, and low to medium-volume production for high-reliability applications. Utilizing our new state-of-the-art equipment and our 45+ years of process expertise, we enable customers to transition from prototype to low-volume production seamlessly.

Services to meet your advanced assembly and packaging needs:

|

|

Access to advanced packaging as a service, with no long-term commitments. This allows companies to conduct low-risk experiments, process development, and accelerate the time to market without having to purchase expensive capital equipment.

Access to advanced packaging as a service, with no long-term commitments. This allows companies to conduct low-risk experiments, process development, and accelerate the time to market without having to purchase expensive capital equipment.

|

|

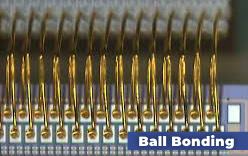

| EQUIPMENT | SPECIFICATION | CAPABILITY |

| TPT HB-16 Wire Bonder |

0.7 mil to 3.0 mil (17-75um) round wire (wedge or ball) |

Gold and Aluminum Wedge Bonding as well as Gold Ball Bonding and Bumping |

| Tresky T-5300 Die Bonder | 1um placement accuracy (application dependent) 20g to 4kg bond force |

3D packaging of MEMS, VCSEL, Photonics, etc. Epoxy or eutectic die attach Flip-chip attach Epoxy dispense or pin transfer |

| Keyence VHX 7000N Digital Microscope | 20x to 2,000x zoom optics +/- 60 degree viewing angle Coaxial, Oblique, and back-lit illumination Depth composition Image stitching |

Sub-micron resolution images |

| XYZTEC Condor Sigma Pull/Shear Tester | Tests from 1 gram to 200 kg force 24-bit resolution 6 Sensors in Rotating Turret |

Fine Wire Pull Test (Destructive and Non-Destructive). Ribbon Pull Test (Destructive and Non-Destructive). Die Shear Test Automatic Testing Capable |

Search Tags: